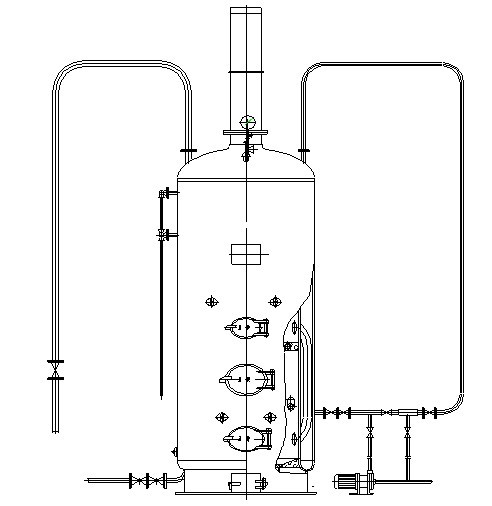

Introduction of vertical coal-fired boiler

LHC series (vertical double-layer grate reverse firing) coal-fired steam boilers are the advantages of similar products in the market of our factory. After improvement, they are carefully designed and manufactured. This type of boiler is composed of head, shell, furnace liner, furnace liner top, smoke (fire) pipe, water-cooled grate pipe and other components. The combustion equipment adopts the double-layer grate reverse firing technology. The upper grate is composed of water-cooled grate tubes, and the lower grate is an ordinary cast iron bar grate. Fuel is added to the grate through the upper furnace door and burned from bottom to top. The combustion products flow down through the grate from top to bottom, and part of the unburned coal (including cinder) leaks to the lower grate to continue combustion. At the same time, the volatile matter in the upper grate coal that has not been completely burned is fully burned in the furnace between the upper and lower grates. After passing through the inner wall of the grate tube and the furnace liner, the high-temperature flue gas generated by combustion is discharged into the atmosphere through the cupola and chimney through the smoke (fire) pipe and horizontal water pipe< br /> LHC boiler has high thermal efficiency, which meets the requirements of jb/t10094 general technical conditions for industrial boilers. The emission concentration of SO2 and soot is better than gb13271 emission standard of air pollutants for boilers. The blackness of flue gas is below lingman level 1. It is an energy-saving and environmental friendly thermal energy equipment< br /> LHC boiler has compact structure, small volume, light weight, convenient transportation, simple installation, small floor area, simple foundation, low investment, convenient operation, operation, maintenance and repair< br /> LHC boiler has strong adaptability to coal types. It is not only suitable for class II bituminous coal, but also can be mixed with other types of bituminous coal. It is an ideal equipment for steam, bathing and drinking water in enterprises, institutions, schools, hotels and catering service industries< br />