Introduction of horizontal coal-fired boiler

This series of products is a three return water fire tube boiler with a horizontal drum arranged longitudinally. The two sides of the furnace are equipped with water-cooled wall tubes, and two groups of smoke tubes are arranged in the drum. The boiler is equipped with a drum and an induced draft fan for mechanical ventilation, and the combustion equipment adopts a fixed grate< br /> The coal burns on the grate, and the flame passes through the burnout chamber on the upper part of the rear arch, enters the first group of smoke pipes upward to the front smoke box, then folds back from the front smoke box, enters the second pipe group, and then enters the dust collector through the waste heat utilization device, and is pumped to the chimney by the induced draft fan< br /> The fuel of this series of boilers is firewood. The boiler smoke and dust emission shall comply with gb13271-2001 emission standard of air pollutants for boilers, the boiler water quality shall comply with the requirements of gb/t1576-2008 industrial boiler water quality, and the boiler installation shall comply with gb50273-2009 code for construction and acceptance of boiler installation engineering< br /> Before the boiler is used, it must go through the registration procedures with the special equipment management department of the local bureau of quality and technical supervision in accordance with the boiler use registration measures. The stoker can only operate the boiler after obtaining the stoker operation certificate, and can only operate the boiler that is not higher than the examination qualification category< br />

DZL series:

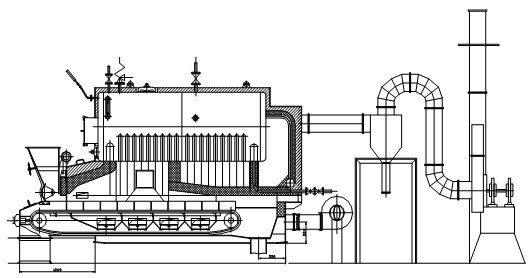

This series of products are three return water fire tube boilers. Water wall tubes are installed on the two sides of the furnace, and two groups of smoke tubes are arranged in the drum. The boiler is equipped with drums and induced draft fans for mechanical ventilation. The combustion equipment adopts light chain grate, and scraper slag extractors can be installed to mechanize coal feeding and slag discharge< br /> After the coal falls onto the grate from the coal hopper and enters the furnace, the radiant heat is reflected by the parabolic front arch to promote its rapid ignition. The flame is burned out through the upper part of the rear arch, and the flue gas enters the first group of flue pipes to the flue box upward, then turns back from the front flue box and enters the second pipe group, and then enters the dust collector through the cast iron economizer or other waste heat utilization devices, and is pumped to the chimney by the induced draft fan< br /> The boiler fuel of this series is class II bituminous coal< br /> The boiler water quality shall meet the requirements of gb/t1576-2008 industrial boiler water quality. After the boiler is equipped with a dust collector, the smoke and dust emission shall comply with gb13271-2001 emission standard of boiler air pollutants, and the boiler installation shall comply with gb50273-2009 code for construction and acceptance of boiler installation engineering< br /> Before the boiler is used, it must go through the registration procedures with the special equipment management department of the local bureau of quality and technical supervision in accordance with the boiler use registration measures. The stoker can only operate the boiler after obtaining the stoker operation certificate, and can only operate the boiler that is not higher than the examination qualification category